Saigon cinnamon (Vietnamese cassia) is the preferred cinnamon for food manufacturing due to its high essential oil content (3–5%), heat stability, and consistent flavor performance during baking, extrusion, and processing. Manufacturers use it in bakery, beverages, spice blends, and confectionery where strong aroma retention and batch-to-batch consistency are required.

Saigon Cinnamon for Food Manufacturing: Applications, Specifications & Sourcing Guide

For food manufacturers, Saigon cinnamon is a precision ingredient. Its potent, consistent, and heat-stable flavor profile makes it a cornerstone for product development and large-scale production. This guide explains why Vietnamese (Saigon) cassia cinnamon is the industry standard for manufacturing and how to source it for optimal performance in your production line.

1. The Manufacturing Advantage: Why Saigon Cinnamon is the Industry Choice

Saigon cinnamon isn’t chosen by accident. Food manufacturers prioritize it for three concrete reasons that impact the bottom line:

-

Superior Flavor Potency & Cost-in-Use: Its high essential oil (EO) content (typically 3-5%) delivers a stronger flavor impact per gram compared to other cassia types. This means you can use less to achieve the same sensory effect, improving your cost-in-use efficiency.

-

Exceptional Thermal Stability: The bold, sweet-spicy profile holds up consistently through high-temperature processes like baking, extrusion, and retorting, ensuring the final product tastes as intended.

-

Batch-to-Batch Consistency: Reliable sourcing from established Vietnamese regions like Yen Bai and Quang Nam ensures minimal seasonal variation, which is critical for maintaining uniform taste in your products year-round.

Internal Link: To understand the grading behind this consistency, see our guide on Vietnamese Cinnamon Grades Explained.

2. Key Manufacturing Applications & Technical Specifications

Here’s how Saigon cinnamon translates into major food industry segments.

Internal Link: Read more about Essential Oil content (EO).

3. Sourcing for Production: Forms, Specs & Compliance

To integrate cinnamon seamlessly into your manufacturing, precise specifications are non-negotiable.

-

Optimal Forms for Manufacturing:

-

For Grinding/Blending: Broken Pieces (Cassia Split) or Cigarette Cut. More cost-effective than whole sticks for in-house grinding.

-

For Direct Inclusion: Ground Cinnamon at a specified mesh size (e.g., 60 mesh for baking, 80+ mesh for fine confectionery).

-

For Extraction: High EO% Broken Pieces or dedicated cinnamon chips to maximize oil yield.

-

-

Mandatory Technical Specifications:

-

Essential Oil Content: Define a minimum (e.g., 3.8%) for flavor guarantee.

-

Moisture Content: Strictly ≤ 13.5% for shelf stability and safe grinding (reduces caking and microbial risk).

-

Particle Size Distribution: For ground cinnamon, request a sieve analysis to ensure it fits your process (e.g., “95% through 60 mesh”).

-

Microbiological Standards: Must meet ISO or ASTM standards for spices (Total Plate Count, Yeast/Mold, E. coli, Salmonella absent).

-

-

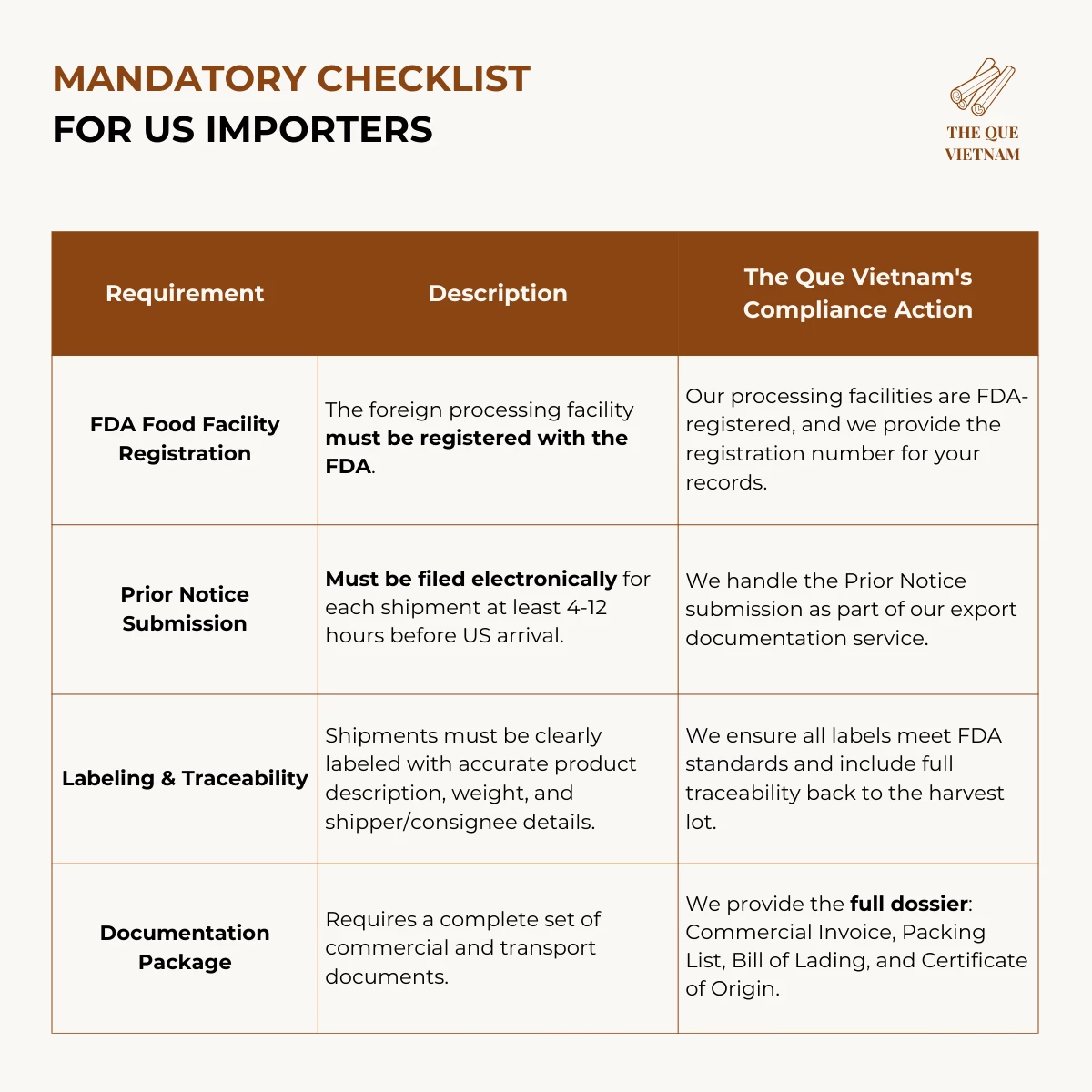

Compliance & Documentation: Your supplier must provide a comprehensive Certificate of Analysis (COA) and all necessary food safety documentation (HACCP, ISO 22000). For EU-bound products, a coumarin content report is essential.

Internal Link: Ensure your documentation is complete with our guide to Cinnamon Export Documents & Certifications.

4. Evaluating Your Cinnamon Supplier: A Manufacturer’s Checklist

Partner with a supplier who understands industrial needs. Use this checklist:

-

Technical Support: Do they have the expertise to recommend forms and specs for my specific application?

-

Consistency Guarantee: Can they provide COAs for multiple consecutive batches to prove consistency?

-

Scale & Reliability: Do they have the capacity and logistics to support my volume needs and just-in-time delivery?

-

Proactive Communication: Do they alert me to harvest variations or potential supply shifts?

-

Value-Added Services: Can they provide custom grinding, blending, or technical data sheets for my R&D team?

Formulate with Confidence: Partner with a Industrial-Grade Supplier

Your cinnamon should be as reliable as any other engineered ingredient in your formula. Sourcing from a partner who prioritizes the technical needs of food manufacturing eliminates variability and simplifies compliance.

At The Que Vietnam, we specialize in supplying B2B clients with specification-driven Saigon cinnamon that performs consistently in demanding production environments.

🧪 Request a Manufacturing-Grade Sample Kit

Contact The Que Vietnam’s Technical Sales Team to:

-

Receive application-specific samples (ground, broken, sticks) with full COAs.

-

Get a consultation on optimal form and spec for your product line.

-

Discuss volume pricing and guaranteed quality parameters for your next production run.

Follow The Que Vietnam on Linkedin & Facebook for most updated news!

FAQs for Food Manufacturers

A: Start with a side-by-side application test against your current cinnamon. Use it in your flagship product (e.g., a cookie or spice blend) and measure the sensory difference and potential dosage reduction. Request small batch samples (5-10kg) from your supplier for R&D trials.

A: While premium grades (higher EO%, better roll) cost more per kilogram, their superior potency often lowers your cost-per-unit-of-flavor. Calculate based on your required dosage—the more potent the cinnamon, the less you may need to use.

A: This is a combination of sourcing and handling. Source cinnamon with high initial EO% and proper moisture control. Ensure your own storage is cool, dark, and dry. Using cinnamon in whole or broken form until the last possible processing stage also helps retain volatile oils.

A: Because we understand your language—consistency, specs, and supply chain reliability. We don’t just sell cinnamon; we provide batch-guaranteed, specification-led ingredients backed by full traceability and documentation designed for factory QA/QC audits.

Saigon cinnamon offers strong aroma, stable performance, and suitability for industrial processing.

Cut, broken, or ground cinnamon is commonly used, depending on processing needs.

Aroma consistency, oil content, moisture control, and particle size are critical.

By reviewing specifications, compliance documentation, supply reliability, and communication quality.