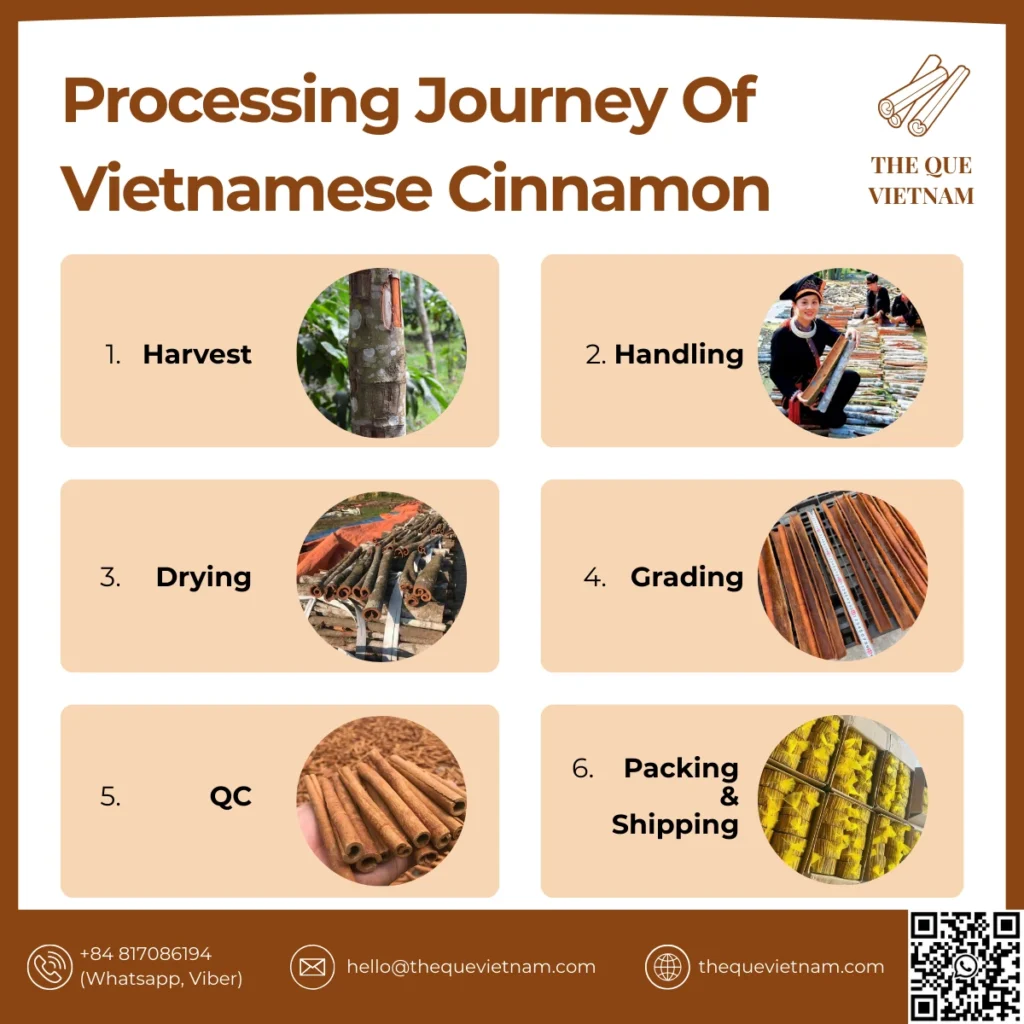

Cinnamon processed for export typically undergoes post-harvest handling, controlled drying, grading, cutting, quality inspection, and export packing. Each stage affects moisture stability, aroma retention, and shipment reliability, making processing standards critical for international buyers.

How Vietnamese Cinnamon is Processed for Export: A Buyer’s Guide to Quality

For international buyers—from food manufacturers to spice distributors—understanding the processing journey of Vietnamese cinnamon is crucial. It’s the key differentiator between a generic commodity and a consistent, high-quality ingredient for your products.

This isn’t just about sticks in a bag; it’s about moisture control, grading precision, and export-ready packing that ensures the cinnamon you receive performs perfectly in your supply chain.

At The Que Vietnam, we believe transparency builds trust. This guide walks you through the critical stages of processing Cassia cinnamon from Vietnam (often called Saigon Cinnamon), highlighting what professional buyers should look for in a supplier.

1. Post-Harvest Handling: Protecting the Raw Quality

The journey begins right after harvest. Careful handling is essential to:

Prevent contamination from soil and debris.

Maintain the structural integrity of the bark for optimal drying.

- Prepare batches for uniform drying.

Buyer Insight: Poor initial handling can trap moisture or impurities, leading to mold or inconsistent flavor later. Ask suppliers about their farm-to-warehouse protocols.

2. Drying Methods & Moisture Control: The Heart of Stability

This is the most critical phase for shelf life and aroma. The goal is to reduce moisture to a safe level (typically below 12-14% for export) to prevent microbial growth while locking in the essential oils that give Vietnamese cinnamon its potent, sweet-spicy character.

Sun-Drying vs. Controlled Mechanical Drying: While traditional, sun-drying is weather-dependent. Modern suppliers use temperature-controlled dryers for consistent, year-round results that meet strict international food safety standards (like HACCP).

Why It Matters to You: Improper drying leads to weight loss in transit, potential for aflatoxins, and diminished aroma—directly impacting your cost and product quality.

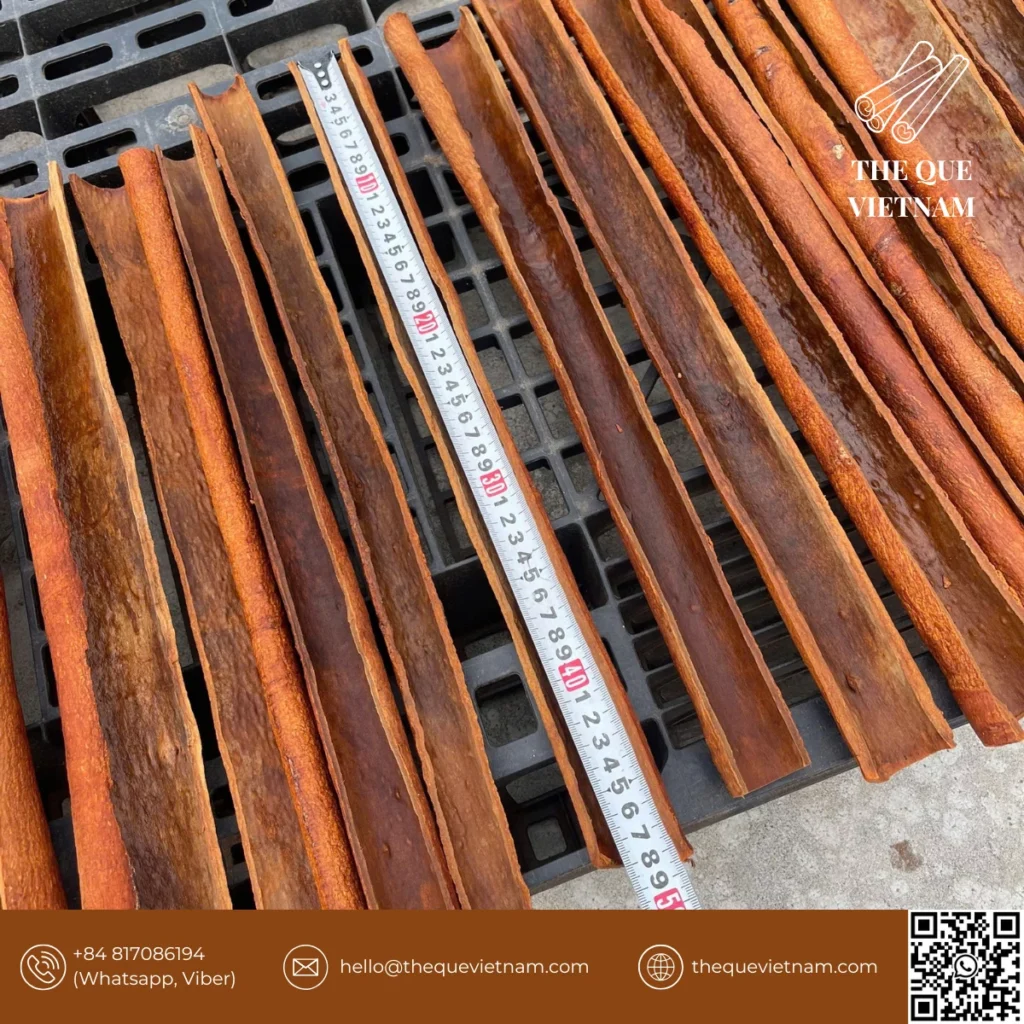

3. Grading & Specification Matching: Precision for Your Application

Not all cinnamon is equal. Dried bark is meticulously graded by:

Thickness & Diameter (e.g., Quills of 0.8-1.2mm, 1.2-1.5mm)

Length & Appearance (clean, unbroken quills)

Color and Aroma Intensity

Your Custom Specifications (e.g., specific coumarin levels, cut sizes)

Buyer Insight: A reliable supplier provides detailed grade sheets and is willing to match samples to your exact needs—whether for whole sticks for retail, broken pieces for tea blending, or specific grades for grinding.

4. Cutting, Rolling & Form Preparation

Based on the order, graded cinnamon is transformed:

Quills (Whole Sticks, Cigars): For retail and culinary use.

- Cinnamon Tubes: For industrial processing

Cinnamon Chips/Broken Pieces: For extraction, teas, and grinding.

- Ground Cinnamon: Milled to specific mesh sizes (e.g., 60-80 mesh for food manufacturing), often with cryogenic grinding to preserve volatile oils.

Logistics Note: The form significantly impacts shipping volume (CBM) and duty classifications—a good supplier will advise you on the most cost-effective form for your needs.

5. Rigorous Quality Control: The Final Checkpoint

Before any packing, a final inspection ensures:

Batch-to-Batch Consistency in grade and color.

Compliance with agreed specifications (moisture, microbiology).

- Absence of foreign materials (metal, sand, other plant matter).

The Que Vietnam’s Standard: We recommend partners insist on pre-shipment inspection reports and Mill Test Certificates (where applicable) to de-risk the transaction.

6. Export Packing: Ensuring Safe Transit

Packing is strategic, not just protective. Options include:

Inner Bags: Food-grade polyethylene for moisture and aroma barrier.

Outer Cartons/Kraft Bags: Strong, clean, and clearly labeled with product details, lot numbers, and gross/net weight.

- Palletization: Securely palletized and wrapped for container loading, minimizing damage and optimizing space.

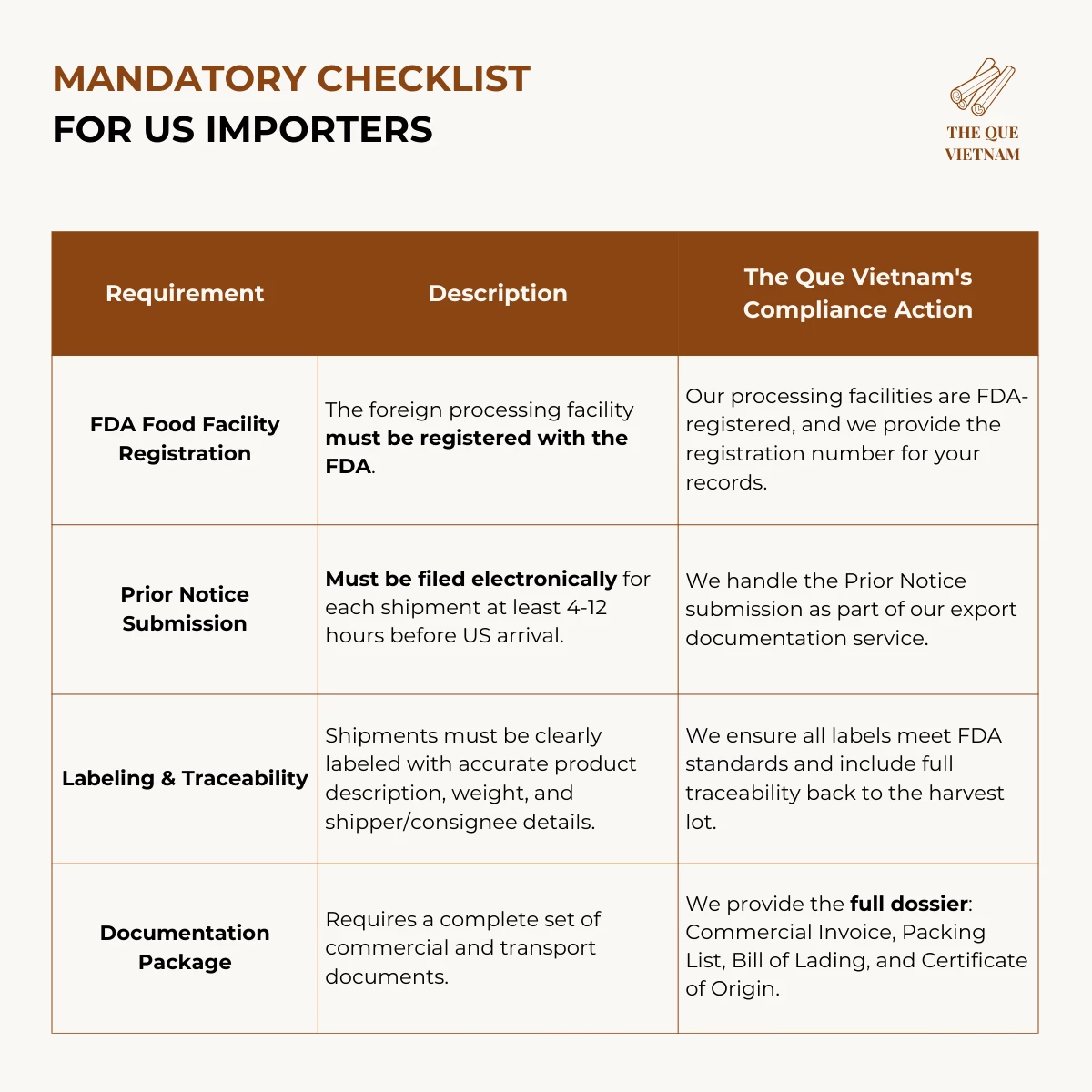

Key Point: Proper documentation inside and outside the carton (including ingredient statements and country of origin) is vital for smooth customs clearance in the US, EU, and Middle East.

7. Why Processing Standards Are Your Sourcing Safeguard

For an importer, a supplier’s processing standards directly protect your:

Product Formulation Consistency: Reliable raw materials mean reliable end products.

Shelf Stability & Safety: Proper drying and packing prevent spoilage and rejections at port.

Brand Reputation: Premium inputs justify premium positioning for your own brand.

Final Perspective for Importers

Export-ready cinnamon is the result of meticulous, controlled processing—not chance. Choosing a Vietnamese supplier who masters these stages—from precision drying to grading transparency and export-compliant packing—is your strongest leverage against quality disputes and supply chain headaches.

Ready to specify your needs with a supplier who details this process? Contact The Que Vietnam’s sourcing team for technical datasheets and samples that match your exact grade and application.

Follow The Que Vietnam on Linkedin & Facebook for most updated news!